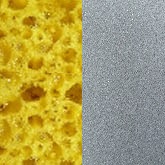

PUR-Ether / Polyether

Foam material, generally with an open cell structure, with low resistance to compression and quick recovery with a polyether base. Very resistant to damp.

- Colour:Black, Grey, White, Red, Yellow, Green, Blue…

- Density: From 15 up to 400 Kg/m3

- Tensile strength: Between 50 and 800 KPa

Description:

Good recovery, comfortable and with good resistance to fatigue and fire (self-extinguishes). Water-resistant. Can be presented in rigid, semi-rigid and flexible form.

Can undergo post-treatment processes such as impregnation, densification or reticulation.

Applications:

- Automotive: For manufacturing adhesive weather-stripping and die-cut parts for cable coverings.

- Home: One of the most common uses is polyurethane sponges used for personal and general hygiene.

- Packaging: For making cast and die-cut parts for protective and presentation packaging.

Supply form:

Can be die-cut, cut, arbour pressed, milled, cast, welded (also with other foams or materials), with adhesive.