Die-Cut Joints

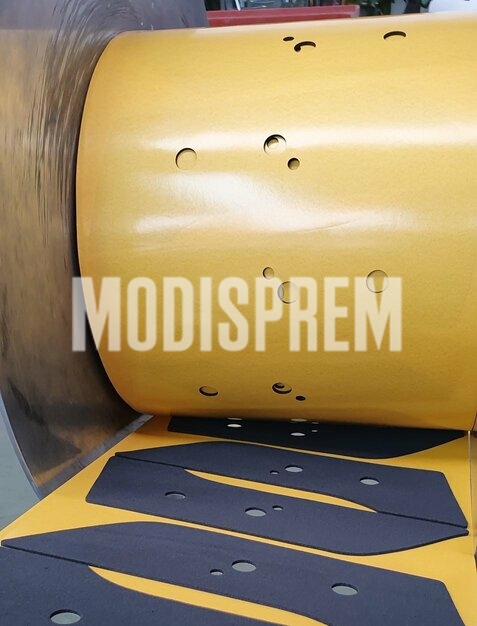

The punching process allows us to obtain parts with clean cuts and very precise dimensional tolerances, thanks to the perfect combination of knife cutting and the pressure exerted by the press.

By using die-cutting, we are able to manufacture a large range of parts with minimal dimensional tolerances.

The diversity of our machines allows us to die-cut a diverse range of shapes, so we can adapt to almost any part size.

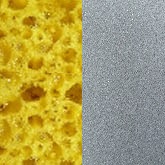

We can die-cut a wide variety of materials in different widths and thicknesses.

Parts can also be self-adhesive, if required by customer specification.

A common production method is Kiss cutting, which involves cutting the material and the adhesive, without cutting the protective liner. This makes it easier to remove and then assemble the pieces (selective cutting, half-cutting or semi-cutting).

Applications:

- Anti-vibration joints.

- Acoustic (soundproof) and thermal insulation.

- Spacers.

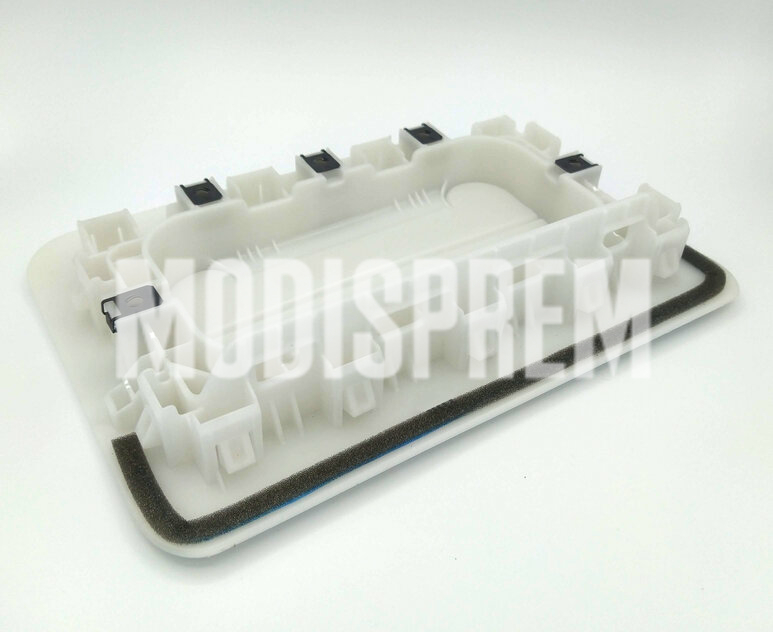

- Sealing gaskets.

- Hollow sealing gasket.

- Brake light gaskets

- Interior acoustic insulation.